Improve processes with innovative mechanical system optimisation support.

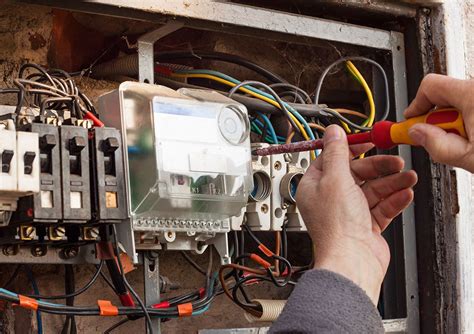

Top Tips for Effective Electric System Troubleshooting

Fixing electrical systems needs a methodical technique, based in an extensive understanding of electric principles and safety and security procedures. By acquainting oneself with circuit elements, using important devices, and adhering to an organized evaluation approach, professionals can effectively recognize and fix issues. The nuances of effective troubleshooting extend past simple technological expertise; recognizing just how to record searchings for and focus on safety and security can dramatically affect end results. As we discover these critical aspects better, it comes to be clear that understanding this process is not just beneficial however important for success in the area.

Understand the Essentials

Comprehending the essentials of electric systems is necessary for efficient troubleshooting, as a solid structure enables service technicians to identify and fix problems extra effectively. An extensive grasp of electrical concepts, such as voltage, existing, resistance, and power, is important in identifying the source of problems. Voltage is the electrical possible difference that drives current via a circuit, while resistance opposes the circulation of present, impacting the total capability of the system.

Familiarity with circuit components, including resistors, capacitors, diodes, and switches, is likewise paramount. Each element plays an unique function in circuit actions and can influence performance when malfunctioning. Additionally, comprehending series and parallel circuit arrangements is important, as these plans influence the distribution of voltage and current within the system.

Service technicians have to be mindful of possible threats, such as shock and brief circuits, to execute secure troubleshooting techniques. By understanding these foundational concepts, technicians boost their capability to perform reliable diagnostics and repair work, eventually leading to boosted efficiency and dependability of electrical systems (electrical system troubleshooting).

Gather Necessary Tools

Reliable troubleshooting of electric systems calls for the best collection of devices to identify and deal with concerns precisely. A fully equipped professional can considerably enhance effectiveness and performance in identifying troubles. Necessary tools consist of a multimeter, which gauges voltage, existing, and resistance, permitting for exact assessments of electric parts. Secure meters are likewise valuable for measuring present without disconnecting the circuit, ensuring safety and ease.

Furthermore, shielded hand tools such as screwdrivers, pliers, and cord pole dancers are essential for securely manipulating electrical links. It is also advisable to have a circuit tester available to confirm the existence of voltage in outlets and wires. For more facility systems, a thermal imaging video camera can assist detect overheating parts, indicating possible failures.

Follow a Systematic Technique

Having actually gathered the proper tools, the next step in repairing electrical systems is to follow an organized technique. A systematic approach ensures that specialists can recognize mistakes efficiently and properly, reducing downtime and stopping unneeded repairs.

Begin by assessing the system's schematic layouts and specs. This includes monitoring each part more information systematically, starting from the power source and functioning towards the load.

Utilize testing devices, such go right here as multimeters and oscilloscopes, to gather objective data concerning voltage, current, and resistance at numerous points within the system. This empirical evidence will lead your troubleshooting initiatives and aid to verify or eliminate possible root causes of failing.

In addition, think about environmental factors that may influence the system's efficiency, such as temperature level variations or dampness ingress. A comprehensive examination of wiring, links, and components will certainly guarantee that all opportunities are represented.

File Your Findings

Detailed documents is crucial in the fixing procedure of electric systems. Exact documents improve the performance of recognizing persisting issues and promote communication among team participants. Each searching for must be carefully noted, including signs observed, examinations performed, and the end results of those tests. electrical system troubleshooting. This method not just aids in recognizing the root cause of the problem yet likewise acts as a reference for future troubleshooting efforts.

Furthermore, keeping a log of parts replaced or repairs done is indispensable. This details sustains supply administration and can help examine the longevity and reliability of details components.

Ultimately, the documentation procedure must be detailed yet concise, enabling easy retrieval and evaluation - electrical system troubleshooting. By focusing on thorough documentation, professionals can produce a useful understanding base that not only aids in present troubleshooting but additionally equips future upkeep efforts, thus improving total system reliability

Prioritize Safety Steps

Identifying the read inherent risks related to electrical systems is critical for guaranteeing safety during troubleshooting. Electrical shock, burns, and equipment damage are simply a few of the possible hazards that technicians encounter. Focusing on precaution is not only a legal obligation yet also an ethical vital that safeguards both the service technician and the surrounding environment.

Prior to starting any kind of troubleshooting job, technicians should wear proper personal protective tools (PPE), consisting of protected gloves, shatterproof glass, and flame-resistant clothes. Making certain that the job location is dry and complimentary of clutter can substantially lower the danger of crashes. It is vital to de-energize circuits before starting any kind of job, verifying that they are not live with the use of a multimeter or voltage tester.

Establishing clear communication protocols with staff member is likewise crucial; this makes sure that everyone recognizes potential hazards and the status of the electrical system being worked with. Last but not least, having an emergency situation action plan in place can show vital in the occasion of an incident. By prioritizing safety actions, technicians can effectively reduce risks and cultivate a much safer work environment.

Verdict

Efficient electric system troubleshooting relies on a thorough understanding of essential principles and a methodical method. Prioritizing security steps ensures the health of individuals included and the stability of the electric system.